impAccelerator Fieldbus Gateway

The Electric Imp impAccelerator™ Fieldbus Gateway provides a platform for customers to rapidly implement secure fieldbus-to-cloud connectivity for a variety of industrial use-cases. Based on the Electric Imp imp005 module, the Fieldbus Gateway gives engineers an easily customizable and programmable lightweight gateway platform that can support a wide range of fieldbus systems, protocols and custom functionality to securely enable industrial control and monitoring applications.

If you are new to the Electric Imp Platform, we recommend that you first work through the Fieldbus Gateway Getting Started Guide, which will show you how to create a free Electric Imp account, configure your Fieldbus Gateway for Internet connectivity, and introduce you to the process of creating connected products using the Platform.

Application Examples

Thanks to the Electric Imp Platform’s reliable networking and robust security — delivered through the impCloud™ and impOS™ — and the imp005 module’s ability to run fully customizable application software, the Fieldbus Gateway can be used to kick-start the development of a wide range of industrial applications, including:

- Industrial Modbus-Internet gateway to securely connect isolated Modbus RTU (RS-485) or Modbus TCP (Ethernet) devices or subsystems to enterprise production systems.

- HVAC-Internet gateway to remotely monitor and control industrial heating, cooling and ventilation systems.

- Internet gateway and controller for Power over Ethernet (PoE) lighting systems.

- Internet gateway for secure connectivity retrofit of products with a data port (for example, USB or UART), such as printers, scales, scanners, and other consumer and industrial devices.

- BACnet-Internet gateway to retrofit existing BACnet (RS-485) systems with connectivity to building management systems.

- Low-cost and highly secure alternative to industrial Linux gateways for many use cases such as process monitoring or protocol conversion (using the on-board XBee® or mikroBUS™ sockets to attach a variety of I/O interfaces).

Open Source Design And Optimized Bill Of Materials

The impAccelerator Fieldbus Gateway is an open source design with an optimized Bill of Materials (BoM). This allows customers to seamlessly scale from Proof of Concept to product deployment in volume with cost-optimized hardware designs and reusable software.

For production in 1000-unit volume, the expected BoM for the Fieldbus Gateway design is around $50 (all features included) and less depending on the feature subset, down to below $20 for a basic design.

Key Features

Connectivity

- Dual-band (2.4GHz and 5GHz) 802.11abgn WiFi via RP-SMA antenna (included)

- WAN Ethernet via RJ45 connector

- Isolated LAN Ethernet via second RJ45 connector

- USB 2.0 Low-Speed/Full-Speed host with stack in impOS™

- Isolated RS-485 port with transmit inhibit option

Electric Imp Module

- imp005 (Murata Type 1GC)

Expansion

- Support for MikroElectronica Click™ module via MikroBUS

- Support for XBee module

- Support for Modbus devices

Application Feedback

- User-controllable red, yellow and green front-panel LEDs controlled via imp005 GPIO pins

Power Source Options

- Isolated Class 2 Power Over Ethernet (PoE)

- 8-24V AC/DC

- 5VDC via mini USB connector (power only; no data)

External Features

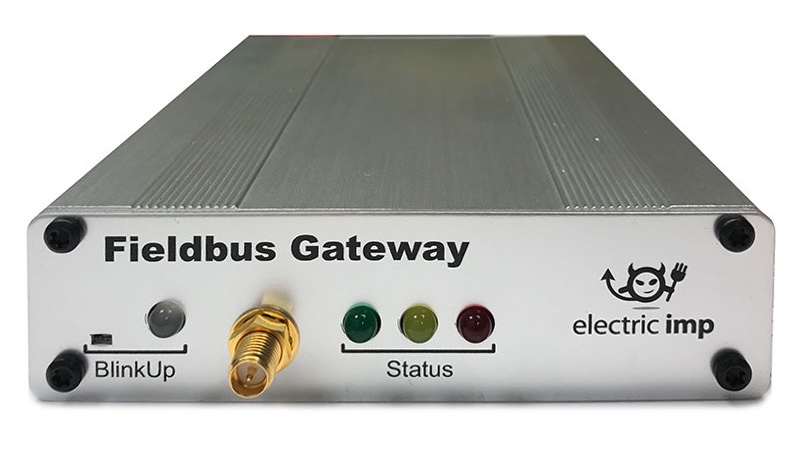

Front Panel

- BlinkUp™ sensor port

- BlinkUp status LED

- RP-SMA connector for external WiFi antenna (included)

- User-controllable application status LEDs

Rear Panel

- 8-24V AC/DC power

- Mini USB power (no data connection)

- Upstream Ethernet RJ-45 connector (with PoE support)

- Isolated downstream Ethernet RJ-45 connector

- USB Type A host connector

- Isolated RS-485 connector

Internal Features

- Header mounting pins for optional XBee module

- Header for optional MikroBUS module

- Serial port (imp005 uart0) header mounting pins (J7) for custom MikroBUS cards

- Electric Imp imp005 module

- SPI Flash programming header (J8)

- Reset button

- Jumper (J2) for RS-485 TX enable

Note The Fieldbus Gateway ships with J2 populated.

Fieldbus Gateway Hardware Details

RS-485

The isolated RS-485 connector includes an isolated ground connector intended for establishing a signal ground. Pin 1 is the pin closest to the USB type A socket and is labelled on the Fieldbus Gateway PCB.

| Terminal | Role |

|---|---|

| 1 | GND |

| 2 | Data B |

| 3 | Data A |

The imp005’s UART2 bus is dedicated to the RS-485 port and the module’s GPIO pin L is utilized to control the data direction: the data direction line must be set to be high for transmission. Transmission from the Fieldbus Gateway can be disabled via hardware control by removing jumper J2 on the fieldbus accelerator PCB.

| imp005 Pin | Function |

|---|---|

| UART2_TX | Transmit |

| UART2_RX | Receive |

| L | Data direction: High for TX, Low for RX |

Note For TX, jumper J2 must be populated.

USB Host Port

The Fieldbus Gateway can operate as a USB host for USB 1.1/2.0 devices using the USB A connector on the PCB. Only one USB device may be connected at any one time, and USB hubs are not supported. Please see the impOS™ USB API for further details on the classes used to manage the Fieldbus Gateway’s USB connection.

The USB port supplies a current-limited 5V for USB devices with maximum recommended load of 500mA. USB power is controlled by the imp005’s GPIO pin R and overcurrent on USB events are reported via GPIO pin W. For more information, please see the imp005 Hardware Design Guide.

| imp005 Pin | Function |

|---|---|

| R | USB power enable |

| W | USB overcurrent indication |

| USB2_DP | D+ |

| USB2_DN | D- |

We have now released a Squirrel library which provides a wrapper for the imp API’s usb object and its methods. Please see the library documentation here.

Isolated LAN Ethernet Port

The Fieldbus Gateway has a downstream port intended to provide access to Ethernet-equipped industrial equipment such as PLC controllers. The downstream port is implemented using a Wiznet W5500 SPI-to-Ethernet bridge and uses the W5500’s integrated PHY. The W5500 is accessed using the imp005’s hardware.spi0 peripheral and the active-low chip select (nCS) pin dedicated to hardware.spi0. The W5500 interrupt and reset pins are connected to imp005 GPIO for additional control.

Note The downstream port does not support auto MDI-X, so if connected directly to another device, a crossover cable may be required.

| imp005 Pin | Function |

|---|---|

| SPI0_SCLK | Clock |

| SPI0_MISO | Controller In, Peripheral Out |

| SPI0_MOSI | Controller Out, Peripheral In |

| SPI0_CS_L | Chip Select |

| XA | Reset |

| XC | Interrupt |

Electric Imp now provides a driver library for the W5500.

WAN Ethernet Port

The WAN Ethernet port allows the imp005 to connect to the Electric Imp impCloud via a local, Internet-connected wired network. It is provided for applications where WiFi is not available, or the stability of a wired connection is preferred. impOS includes support for the LAN8720A Ethernet PHY used on the Fieldbus Gateway.

The LAN port also allows the entire device to be powered from a PoE switch. The accelerator is a PoE class 2 device (6.49W maximum, isolated) and the port supports auto MDI-X.

mikroBUS Header

The Fieldbus Gateway PCB has a populated header compatible with the plug-in Click boards (not included) from MikroElectronica. Click is an ecosystem of available modules adding support for current loop communication, thermocouples, 1-Wire® devices and many others.

Note that a custom endplate may be required in order to expose the I/O on the Clicks. Contact us for CAD files that can be used to make laser-cut endplates if required.

SPI, UART and I²C interfaces are available through the MikroElectronica Click header, and additional Click control signals are connected to the imp005 GPIO and can be controlled via firmware.

Peripherals used by the Click header:

- hardware.spiBCAD

- hardware.i2cJK

- hardware.uart1

- hardware.uart0

| Click Header Pin Number | Name | Description | imp005 Pin |

|---|---|---|---|

| 1 | AN | Analog | M (digital only) |

| 2 | RST | Reset | H |

| 3 | CS | SPI Chip Select | D |

| 4 | SCLK | SPI Clock | A |

| 5 | MISO | SPI Controller In, Peripheral Out | C |

| 6 | MOSI | SPI Controller Out, Peripheral In | B |

| 7 | 3V3 | ||

| 8 | GND | ||

| 9 | GND | ||

| 10 | 5V0 | ||

| 11 | SDA | I2²C Data | K |

| 12 | SCL | I²C Clock | J |

| 13 | TX | UART Transmission to Click | UART1_TX |

| 14 | RX | UART Receive from Click | UART1_RX |

| 15 | INT | Hardware interrupt line | XD |

| 16 | PWM | Pulse Width Modulation signal to Click | U |

Note 5V is available to Click boards, though care must be taken to not drive lines connected to the imp005 to 5V. Please consult the datasheet for the device mounted on the Click board to determine if the logical high of the imp005 will meet the logic level specifications for this device.

XBee Header

To add an XBee module (not included) to the Fieldbus Gateway, you will need to attach the module directly to the Fieldbus Gateway’s motherboard or first fit two 10mm, 2mm-pitch female headers to the board.

The XBee pins are connected to the imp005’s hardware.uart0 peripheral. The UART’s TX and RX pins are connected to the XBee’s DIN and DOUT pins, respectively, and the UART’s CTS and RTS pins connect to their XBee equivalents.

| XBee Pin | imp005 Pin |

|---|---|

| DIN | UART0_TX |

| DOUT | UART0_RX |

| CTS | UART0_CTS |

| RTS | UART0_RTS |

Electric Imp provides an XBee library to help you work with a mounted XBee module to help you interact with the module, and with other modules across a ZigBee network. The library operates through the XBee API mode, communicating through the connected UART (passed into the library’s class constructor).

Please see the library documentation for more information.

Modbus Devices

Electric Imp provides a series of Modbus libraries to help you work with Modbus devices attached to the Fieldbus Gateway:

- Modbus Serial Master — Communicate with Modbus devices via the RS485 and RS232 protocols

- Modbus Serial Slave — Communicate with a Modbus Master via the RS485 and RS232 protocols

- Modbus TCP Master — Communicate with Modbus devices via TCP/IP

- Modbus RTU — Create and parse Modbus Protocol Data Units

User LEDs

The Fieldbus Gateway’s three user-controllable LEDs are connected to specific imp005 GPIO pins as listed below:

| LED | imp005 Pin | Startup State |

|---|---|---|

| Red | P | High |

| Yellow | Q | Low |

| Green | T | High |

The LEDs are configured with the imp005 sinking current to illuminate the LED, and so the imp005 control pin is driven high to extinguish the LED. For example code highlighting the use of the application LEDs, please see the Fieldbus Gateway Getting Started Guide.

Note The control pin for the yellow LED, Pin Q, will be low at power-up. As such, when you power up the Fieldbus Gateway, the yellow LED will be lit until you explicitly turn if off in your Squirrel code.

Power

The Fieldbus Gateway includes a bridge rectifier so there are no polarity concerns for the two-terminal AC/DC power connector. Maximum recommended voltage for operation 38V DC via AC/DC power connector.

PoE and the AC/DC inputs are diode OR’d together.

If either the PoE or AC/DC are being fed with power, the 5V USB input is disabled.

The housing will be one diode drop below the more negative power input on the AC/DC input due to the ground connection via the antenna and PCB.

Programming The Fieldbus Gateway

Sample Code

- XBee/ZigBee Examples

- Getting Started Guide: Hello, World

- Getting Started Guide: Interactive Agents

- PLC-connected Temperature Monitor

- PLC-connected Water Pump Controller

Additional Programming Resources

imp005

Modbus

- Modbus Serial Master Library

- Modbus Serial Slave Library

- Modbus TCP Master Library

- Modbus RTU Library